Food Emulsion

Many natural and processed foods consist either part or wholly as emulsions or have been in an emulsified state at some time during their production such foods include milk, cream, butter, margarine, fruit beverages, salad cream, ice cream, and coffee whitener. Emulsion based food products exhibit a wide variety of different physiochemical and organoleptic characteristic such as appearance, aroma, texture, taste and self-life

milk is low viscosity white fluid, strawberry yogurt is a pink visco elastic gel, and margarine is a yellow semisolid. This diversity is the result of the different sorts of ingredients and processing conditions used to create each type of product

The manufacture of an emulsion -based food product with specific quality attributes depends on the selection of the most appropriate raw materials [e.g., water, oil, emulsifiers, thickening agents, minerals, acids, bases, vitamins, flavour, colorants etc.] and processing conditions [e.g. mixing, homogenization, pasteurization, sterilization, etc.]

Traditionally the food industry largely related on craft and tradition for the formulation of food products and the establishment of processing and storage conditions.

This approach is unsuitable for the modern food industry, which must rapidly respond to changes in consumer preferences for greater variety of cheaper, heather, and more convenient foods in addition the modern industry relies increasingly on large scale production operation to produce vast quantities of food at relatively low cost.

The substances that makes the droplets in an emulsion is referred to as the dispersed or internal phase whereas the substance that makes up the surrounding liquid is called the continuous or external phase.

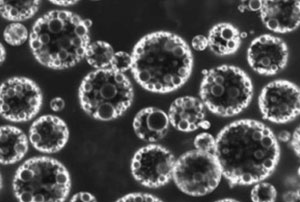

It is also possible to prepare multiple emulsion of the oil in water -in oil or water -in oil- in- water type. for example, a emulsion consists of water droplets dispersed with in larger oil droplets, which are themselves dispersed in an aqueous continuous phase recently, research has been carried out to create stable multiple emulsions which can be used to control the release of certain ingredients, reduce the total fat content of emulsion -based food products, or isolate one ingredient from another the concentration of droplets in an emulsion is usually described in terms of the dispersed -phase volume fraction the process of converting two dispersed -phase volume fraction

General characteristics of food emulsions

- An emulsion consists of two immiscible liquids with one of the liquids dispersed as small spherical droplets in the other most foods,

- The diameters of the droplets usually lie somewhere between0.1 and 100 microns emulsions can be conveniently classified according to the distribution of the oil and aqueous phase.

- A system which consists of oil droplets dispersed in an aqueous phase.

- A system which consists of oil droplets dispersed in an aqueous phase is called an oil-in water or emulsion a system which consists of water droplets dispersed in an oil phase is called a water-in -oil emulsion.

- Emulsifiers are surface- active molecules which absorb to the surface of freshly formed droplets during homogenization, forming a protective membrane which

- prevents the droplets from coming close enough together to aggregate.

- Most emulsifiers are amphiphilic molecules (i.e., they have polar and nonpolar regions on the same molecule).

- The most common emulsifiers used in the food industry are amphiphilic proteins, small-molecule surfactants, and phospholipids.

- Thickening agents are ingredients which are used to increase the viscosity of the continuous phase of emulsions, and they enhance emulsion stability by retarding the movement of the droplets.

- The most common thickening agents used in the food industry are polysaccharides

- A stabilizer is any ingredient that can be used to enhance the stability of an emulsion and may therefore be either an emulsifier or a thickening agent

Typical emulsion Products

| System | Disperse Phase | Continous Phase | Product |

|---|---|---|---|

| Sol | Solid | Liquid | Uncooked Custard, Unset Jelly |

| Gel | Liquid | Solid | Jelly, Jam, Blancmange |

| Emulsion | Liquid | Liquid | Mayonnaise, Milk |

| Solid Emulsion | Liquid | Solid | Butter, Margarine |

| Foam | Gas | Liquid | Whipped Cream, Whisked Egg White |

| Solid Form | Gas | Solid | Meringue, Bread, Cake, Ice Cream |

COTRYDO would like to develop technology for food emulsions as per the customer requirement.

Cotrydo has state of art laboratory facility for emulsion studies and with the expertise and knowledge would developed stable emulsion as per the requirement..

With the In-depth understanding of the emulsion physiochemical properties COTRYDO can scale any process, conceptualize, design and provide complete solution.